Past work

8” Chef knife, full tang handle, Ironwood handle with brass and mosaic pins.

The mosaic pin is made up of stainless, copper, and brass tubes.

A closer look at the "coke bottle" shaped handle.

The remnants of testing the edge on a 1/4" thick magazine.

Finished and ready to sharpen.

All glued and clamped, just waiting for the epoxy to dry. I use G-flex marine grade epoxy.

Getting ready for glue up.

Hand sanded to 800 grit which leaves a nice satin finish.

Hand sanding is tedious but worth the effort.

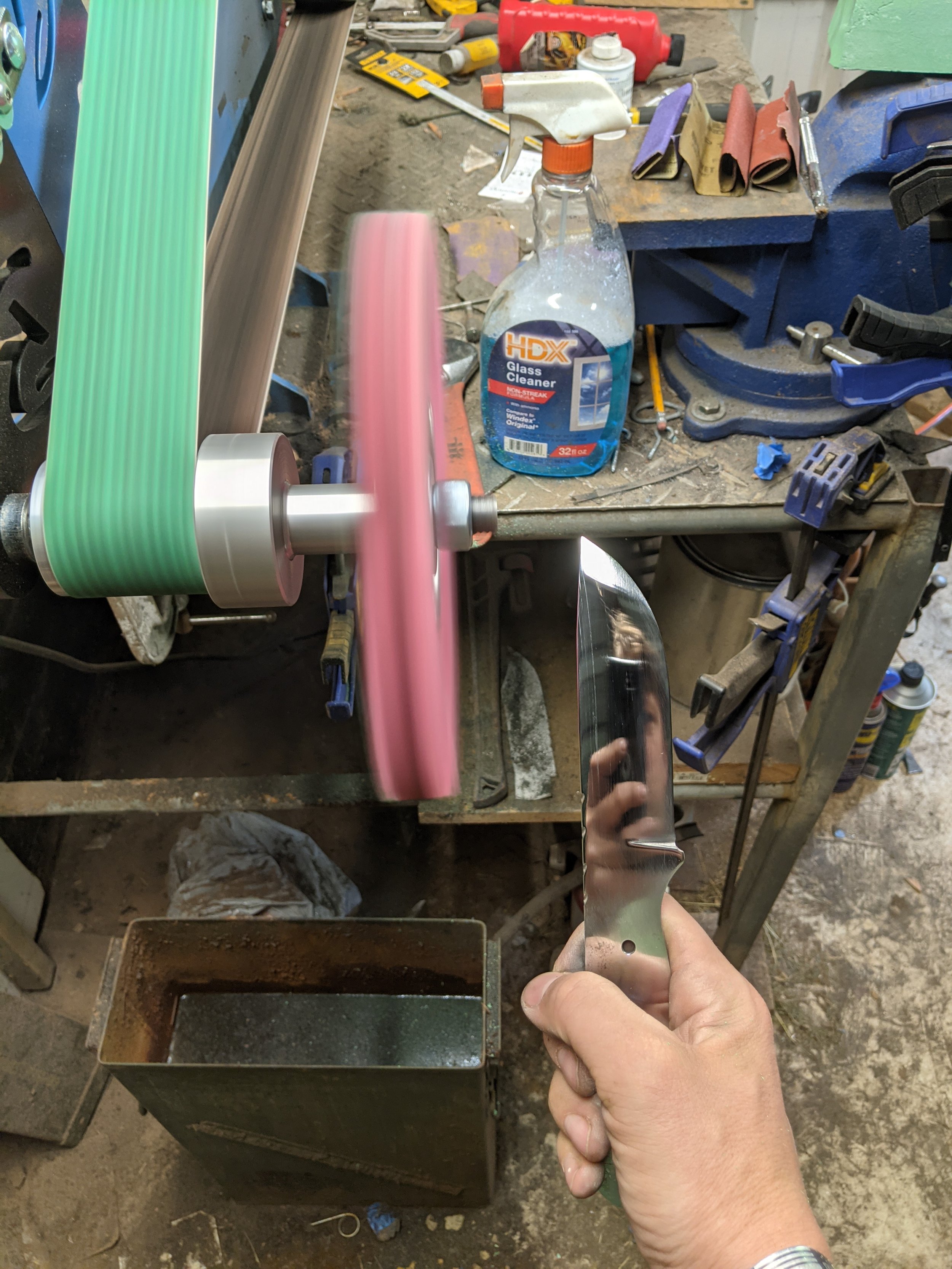

Bevels are rough ground and ready to refine and polsih.

9.5" Brisket slicer, 440c stainless steel, Patagonian Rosewood handle with brass pins.

Shaping the handle starts with a rough block shape.

Next step is to profile the handle to match the tang of the knife.

I rough grind in a "coke bottle" shape to fit in your hand nicely.

Here is a top view where you can see the shape.

A 12" ruler for scale

A close look at my makers mark and the finished handle.

The finished knife. I protect the handles of my knife with Axe wax, a food safe wax made for knives.

6” Kitchen utility, 1084 Sheffield steel, full tang handle, white and pearl resin scales with stainless pins

7.5” Cleaver, 5160 steel, white G-10 Handles. red liner, mosaic pins

4.75” Drop point hunter, 80CrV2 steel, brass guard, Black walnut handle with a brass pin

6” Kitchen utility, 1084 Sheffield steel, full tang handle, blue and pearl resin scales with stainless pins

9.5” Gyuto, 1084 steel, olive wood handle with a blue/bronze resin spacer

6.5” Rigid pipe wrench knife

4.5” Drop point hunter, 1095 steel, Desert Ironwood handle with brass guard and mosaic pin

Closeup view of my makers mark and pin

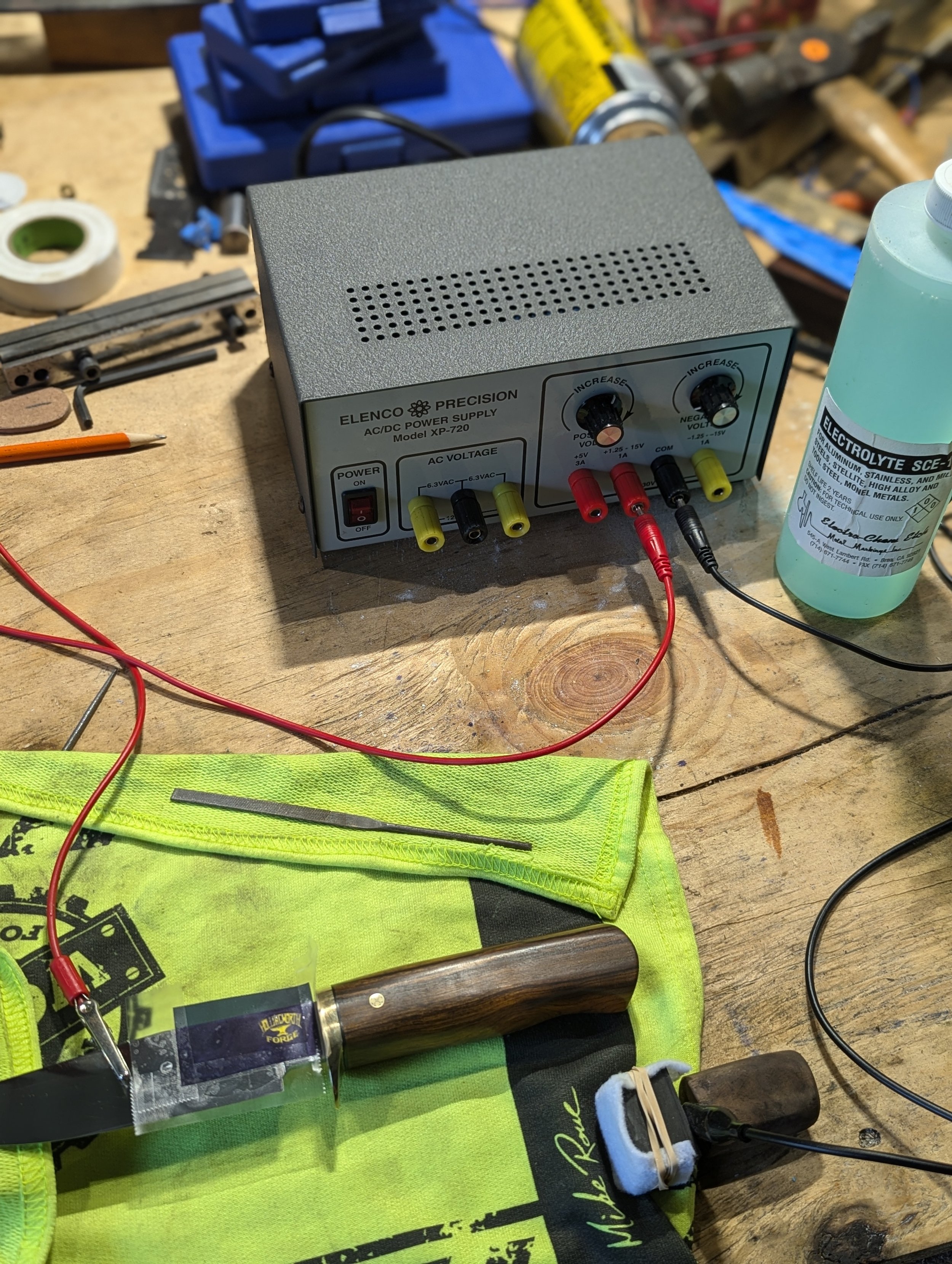

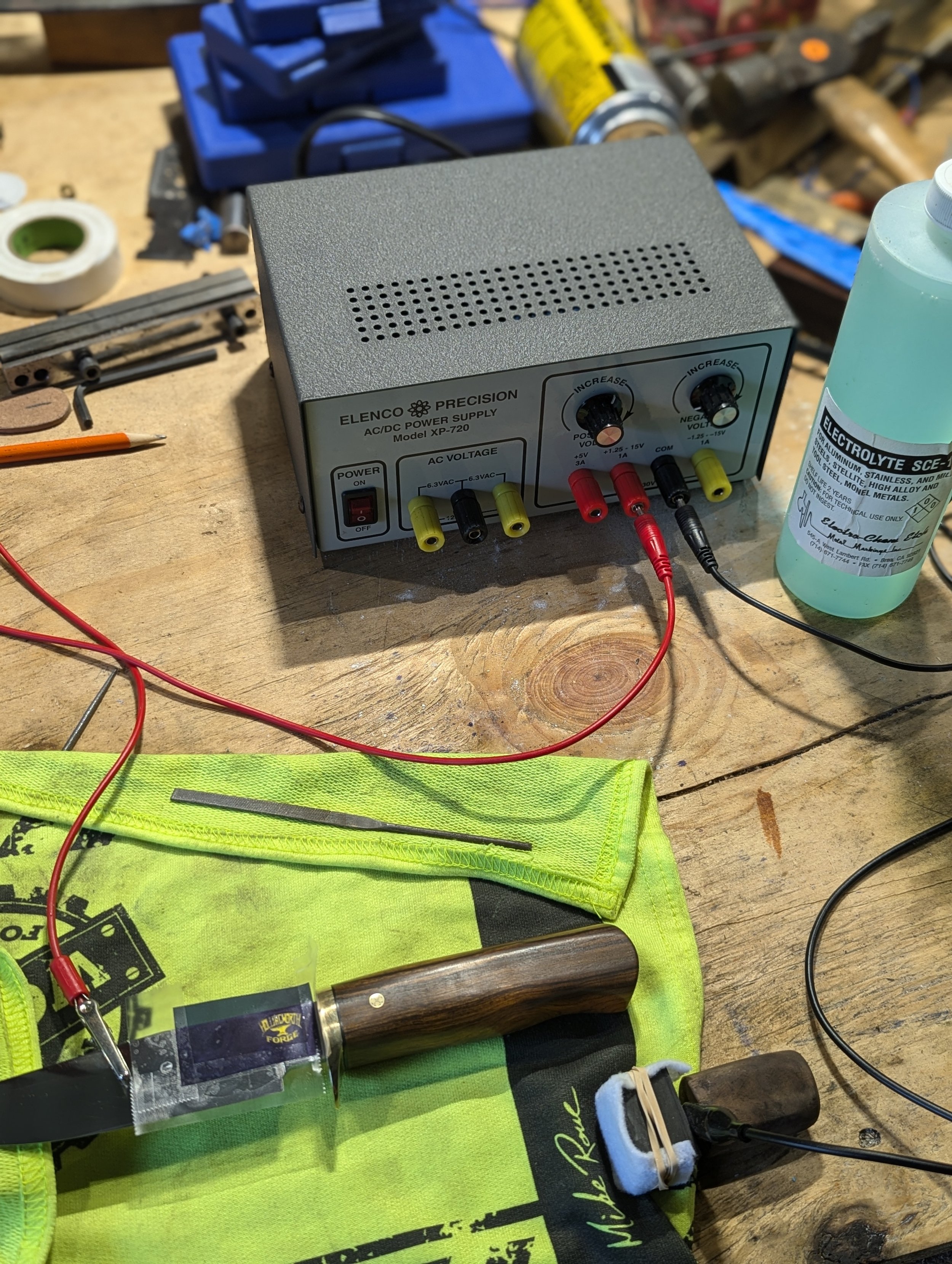

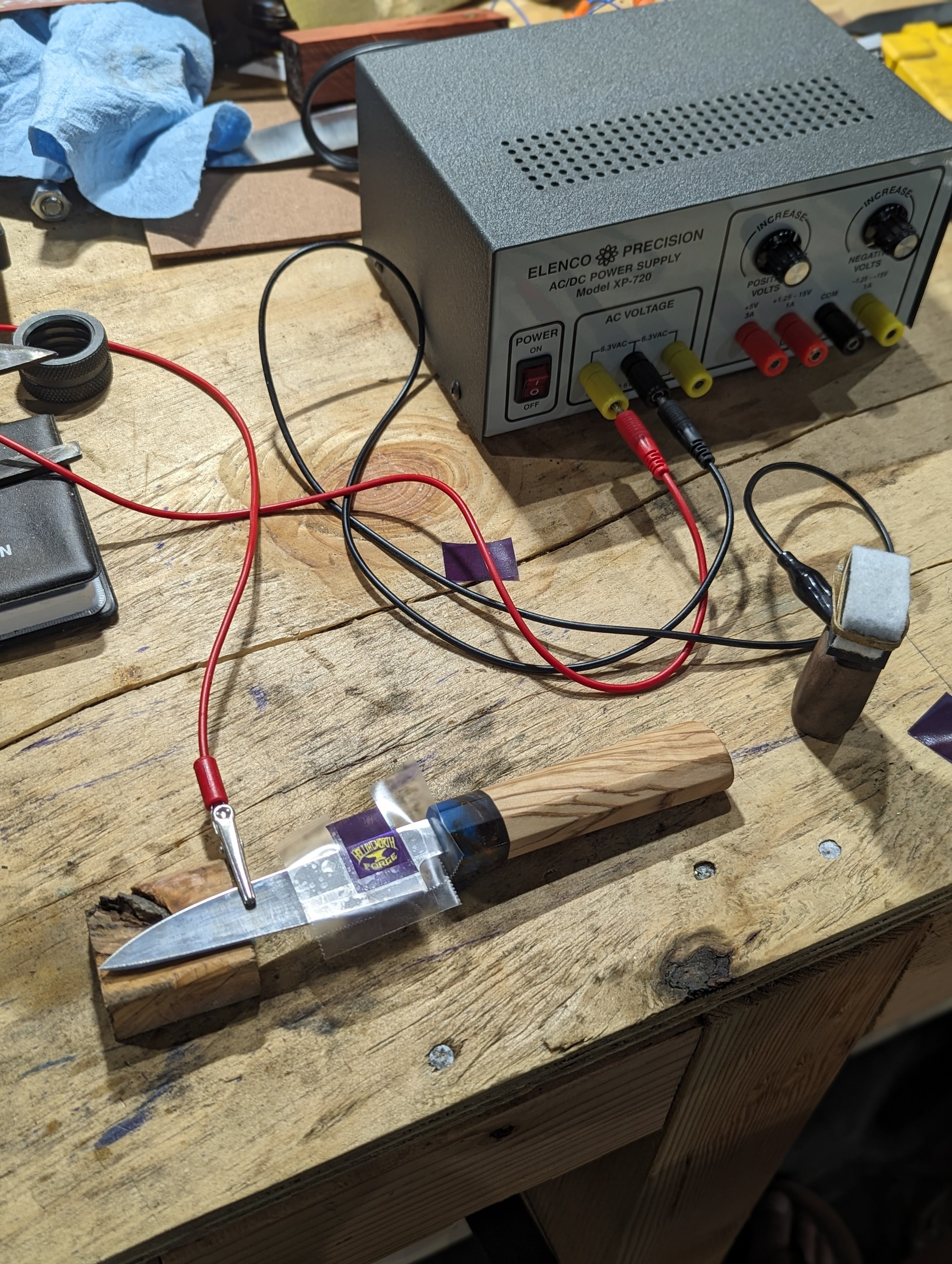

Etching my makers mark with my DIY machine

Clamping everything together for glue up

A look at both blades together after rough grinding

Getting the blade up to quenching temp using tubing so the blade isn't directly in the flame helps to reduce forge scale

4.5” Drop point hunter, 1095 steel, Desert Ironwood handle with brass guard and mosaic pin

Etching my makers mark

Hand sanding the handle

Prepping for glue up

Profile of the guard next to the bar stock I made it out of.

From bar stock to guard.

Tempering jig to make sure the blades stay straight

Getting the blade up to critical temp using indirect heat to reduce forge scale.

Profile of the knives before heat treat.

Filing the shoulders even where the guard fits up.

Starting to get the tip forged out.

Forging the blade.

It all started out with some 1095 bar stock and a piece of Iron wood

6.5” Santoku, 1084 steel, resin and maple burl handle with a black paper Micarta spacer

6.5" Santoku, 1084 steel, resin and maple handle with black paper Micarta spacer

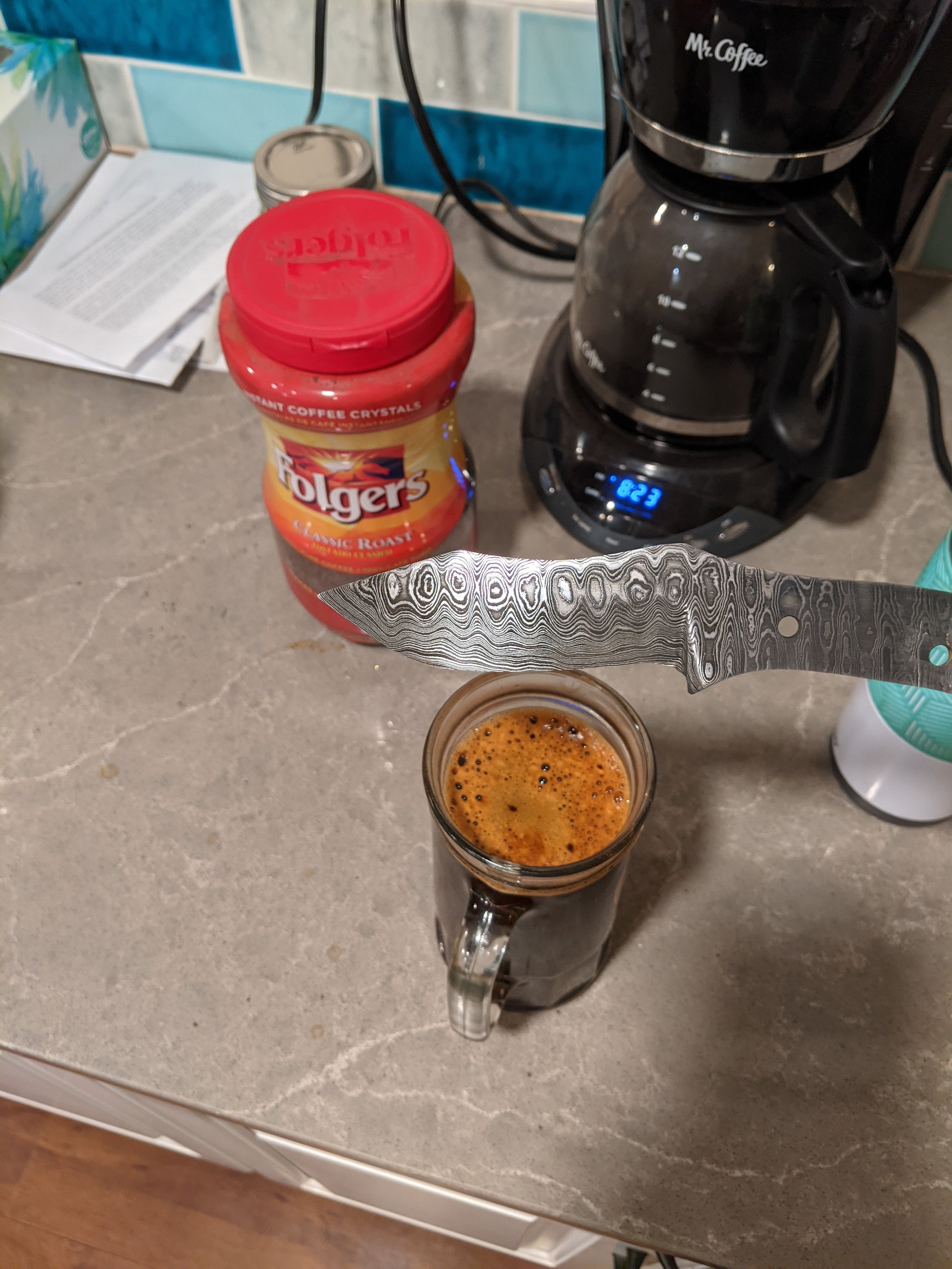

I use Eagle Tears on the steel and Axe Wax on the handles of all my knives to protect them.

Etching my makers mark

Hand sanding the handle.

I use GFLEX marine grade epoxy on all my knives to glue the handles on.

A closeup look at how the blade profile tapers.

Doing a traditional handle fit up using an oak dowel for the handle construction.

The edge of the knife is brought down 0.01" before sharpening to get a razor sharp edge.

The blade is sanded to the final finish before glue up.

Laying out how I want the handle to look.

Filing the shoulders of the tang flush for a perfect fit.

Making sure the blade is nice and flat before I start grinding the bevels in.

A look at handle block before i trim it down into the handle.

The profile of the handle is complete and ready for polishing.

Getting the profile of the blade dialed in before heat treat.

4 3/4” Drop point hunter, 1095 steel, brass guard, purple heart handle with a mosaic pin

4 3/4" hunting knife, 1095 steel, brass guard, purple heart wood with a mosaic pin

4 3/4” Drop point recurve hunter, 1095 steel, brass guard, red heart handle with a mosaic pin

5.5” Santoku, 1084 steel, olive wood handle with a blue/bronze resin spacer

This is the second knife for my personal Japanese inspired kitchen set. I really like the look of the olive wood. It is an oily wood, so it doesn't have to be stabilized for use.

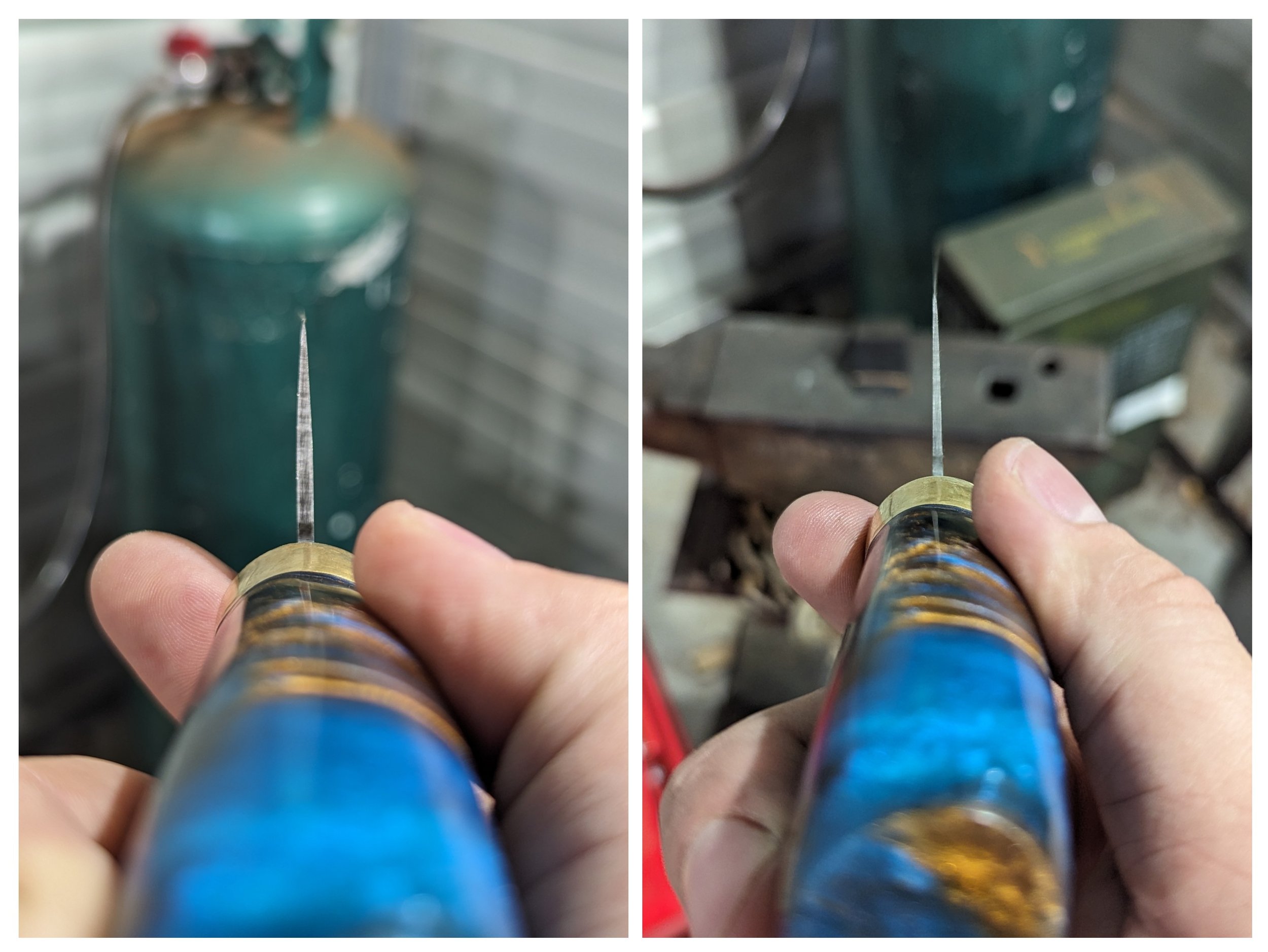

The spine of the knife tapers from 2.5mm to 0.25mm at the tip before the sharpening bevel

I saw someone using their file guide as a way to clamp their knife. I find it useful on knives that are slender/bendy or too long for my clamps.

Getting ready for glue up. I use West Systems G-Flex marine grade epoxy

I went back and etched my makers mark into the steel

Here's a closer look

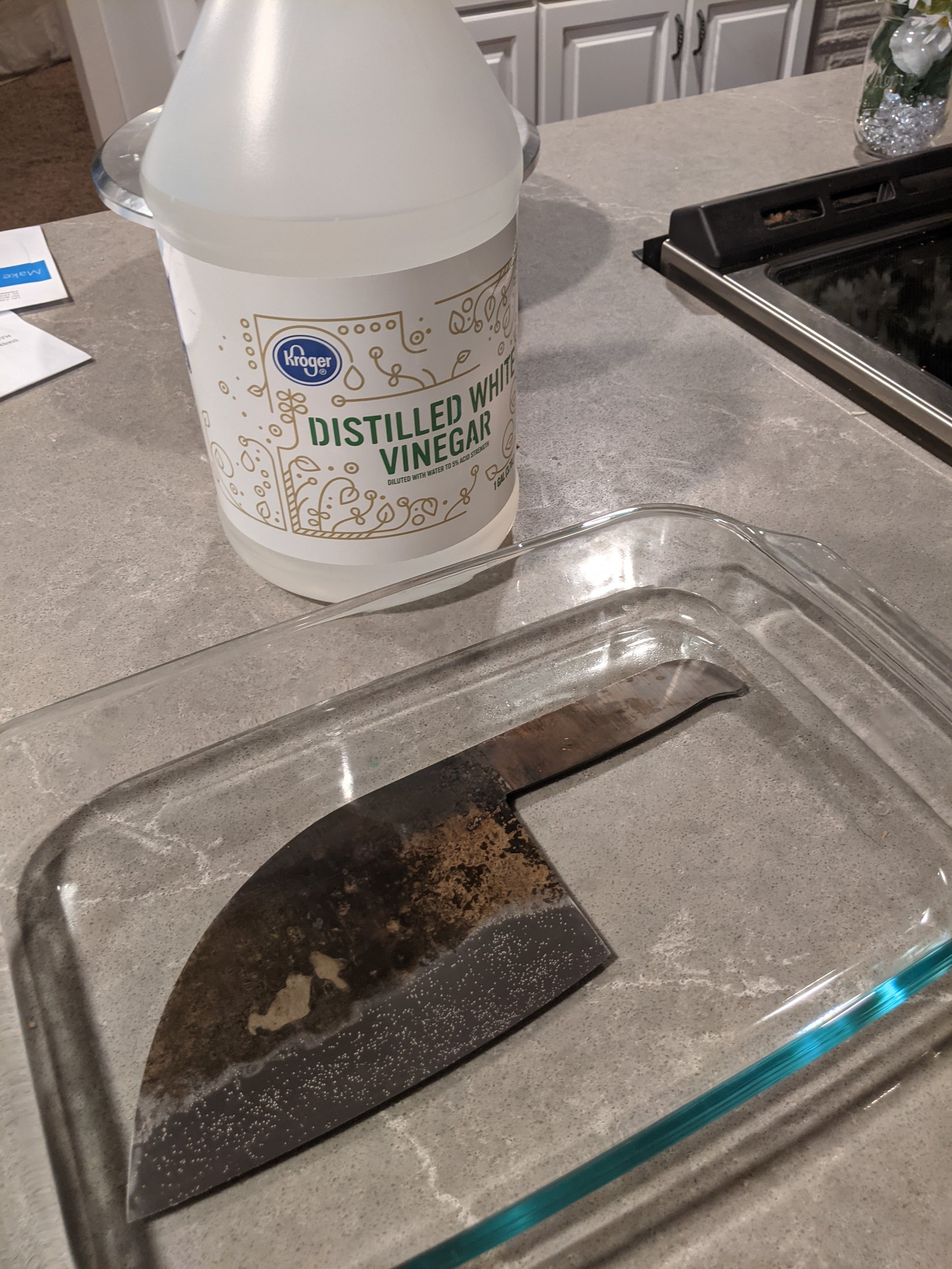

The steel is starting to get some patina

Another look at the start of establishing the patina. If you cut a lot of onions, tomatoes, or other acidic foods, it can help put good oxidation on the steel to help protect it.

4” Petty, 1084 steel, olive wood handle with a blue/bronze resin spacer

11.5” Bowie, 5160 steel, black walnut handle with brass guard and pommel 17.5” overall. Darkened with gun blue

4” Skinner, 1095 steel, cocobolo wood handle, brass pins

5” Hunter, 1095 steel ,brass guard, black walnut handle, brass pin

4.5” Camp knife, 1095 steel, black and green Micarta handle, brass pins and thong tube, black 550 paracord

6.5” Serbian cleaver, 1095 steel, cocobolo handle, brass pins

3.5” belt knife, Damascus steel, purple G-10 handle with brass pins

4” Skinner, 1095 steel, tri-color G-10 handle, brass pins

4” Skinner, 5160 blued steel, black and gray Micarta handle, steel pins

6” Camp knife, 1095 steel, teal acrylic resin handle, brass pins

6” Green River skinner, 1080 steel, dyed camel bone handle, brass pins

4” Viking axe, mild steel body, 5160 steel edge, hickory handle

8” Chef knife, 1084 steel, blue and bronze acrylic resin handle, brass bolster, brass pin